产品介绍

SPECIFICATIONS OF PIPE FITTING

Materials

Type

Outer Diameter

Wall Thickness

Standard

Austenitic

Duplex Steel

Nickel Alloy

Cobalt Alloy

Ferrite

EIbow/Tee/Reducer/Cap

≤2000mm;

≤DN2000;

≤80"≤30.96mm;

≤Sch160ASTM A403

ASTM A815

EN 10253-4

ASTM B366

…Stub End

≤800mm

≤DN800

≤32"Long radius 90 degree reduction elbow is used to connect pipes of different diameters to achieve a 90 degree direction change. Its long radius design reduces fluid resistance, eddy current and pressure loss, and is suitable for high flow systems. Reducer pipes are commonly found in pipeline systems such as petrochemicals, water treatment, HVAC, etc., at pump inlets and outlets, equipment interface adapters, or where smooth steering is required, taking into account efficient transportation and space optimization. The long radius 90 degree reduction elbow is characterized by its long bending radius (generally 1.5 to 2 times the diameter of the pipe), which reduces turbulence and energy loss in the flow by optimizing the fluid flow path, thereby improving the overall efficiency of the pipeline system. Its smooth flow design can effectively reduce the operating load of the equipment and extend the service life of the pipeline and pump equipment.

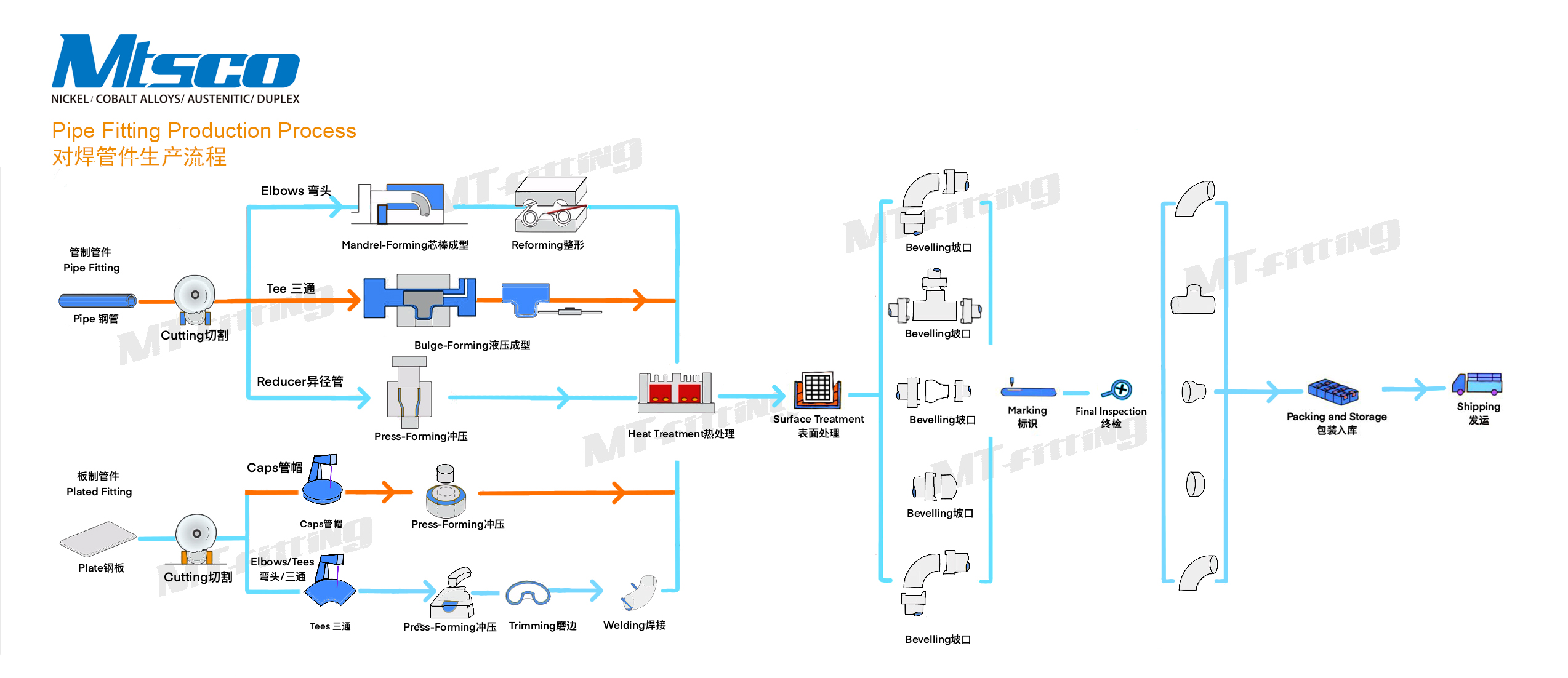

Pipe fitting production process:

1.Cutting: cutting pipes according to size;

2.Forming: cold pressing/hot pushing bending, or die forging;

3.Welding (if split): grinding welds after welding;

4.Heat treatment: eliminating forming stress and improving mechanical properties;

5.Surface treatment: sandblasting, electroplating or coating with anti-corrosion layer;

6.Inspection: dimensional accuracy, pressure testing and non-destructive testing to ensure compliance with standards.

How do we ensure the quality of pipe fittings?

Raw Materials

Secondary inspection of raw materials

Our raw materials come from large factories such as Baosteel, TSINGSHAN, Yongxin...Each batch of raw materials requires MTC and PMI. After the raw materials arrive, we conduct PMI and other inspections again to ensure that they meet the requirements.During Production

Traceability of the production process

Hongdi is equipped with CNC lathe, automatic laser cutting machine, 1,000tons hydraunlic press, elbow mandrel machine and other major productionequ equipment.

Each process is supervised by experienced engineers and technicians. Each link is supervised by professional qc inspectors and photographed for archiving. The entire process uses process cards to ensure accuracy and traceability.Before Shipment

100% inspection before shipment

MTSCO has professional QC team to conduct a series of inspections and experiments on the fittings, including routine appearance, PMI, size, quantity, NDT and other inspections. At the same time, we also conducts mechanical testing, chemical composition analysis, intergranular corrosion and other laboratory tests. For welded pipe fittings we carry out 100% ultrasonic or radiographic testing of the raw material and pipe fittings.

In addition, we also accept third-party inspection, such as SGS, TUV, and BV.Packaging and Container Loading

As A factory complexes supplier, MTSCO has many years of experience in packaging and containerization. Conventional packaging methods are, large one wrapped in cling film, small one molded or wrapped in bubble wrap. The end is protected by pearl cotton. The outside is packed in wooden box/pallet, and the cabinet is reinforced with wooden strips and ropes.

All inspection results and loading process will be documented with photos for your traceability requirements.