产品介绍

SPECIFICATIONS OF PIPE FITTING

Materials

Type

Outer Diameter

Wall Thickness

Standard

Austenitic

Duplex Steel

Nickel Alloy

Cobalt Alloy

Ferrite

EIbow/Tee/Reducer/Cap

≤2000mm;

≤DN2000;

≤80"≤30.96mm;

≤Sch160ASTM A403

ASTM A815

EN 10253-4

ASTM B366

…Stub End

≤800mm

≤DN800

≤32"Elbow 180° is a key steering fitting used in industrial piping systems. Its main function is to make the pipeline change direction by 180 degrees, so as to achieve the purpose of "U"-shaped reflux or steering of the medium in the system. 180-degree elbows are widely used in industries such as petroleum, natural gas, chemical, electric power, metallurgy, pharmaceutical, papermaking, food, and shipbuilding. They are particularly common in heat exchange equipment, cooling systems, steam circulation systems, pressure pipelines, and industrial equipment pipe networks. The product has good corrosion resistance, high temperature resistance, and pressure resistance. It can operate stably under high-intensity working conditions for a long time. It has standardized dimensions, precise tolerances, uniform wall thickness, and standardized port processing.

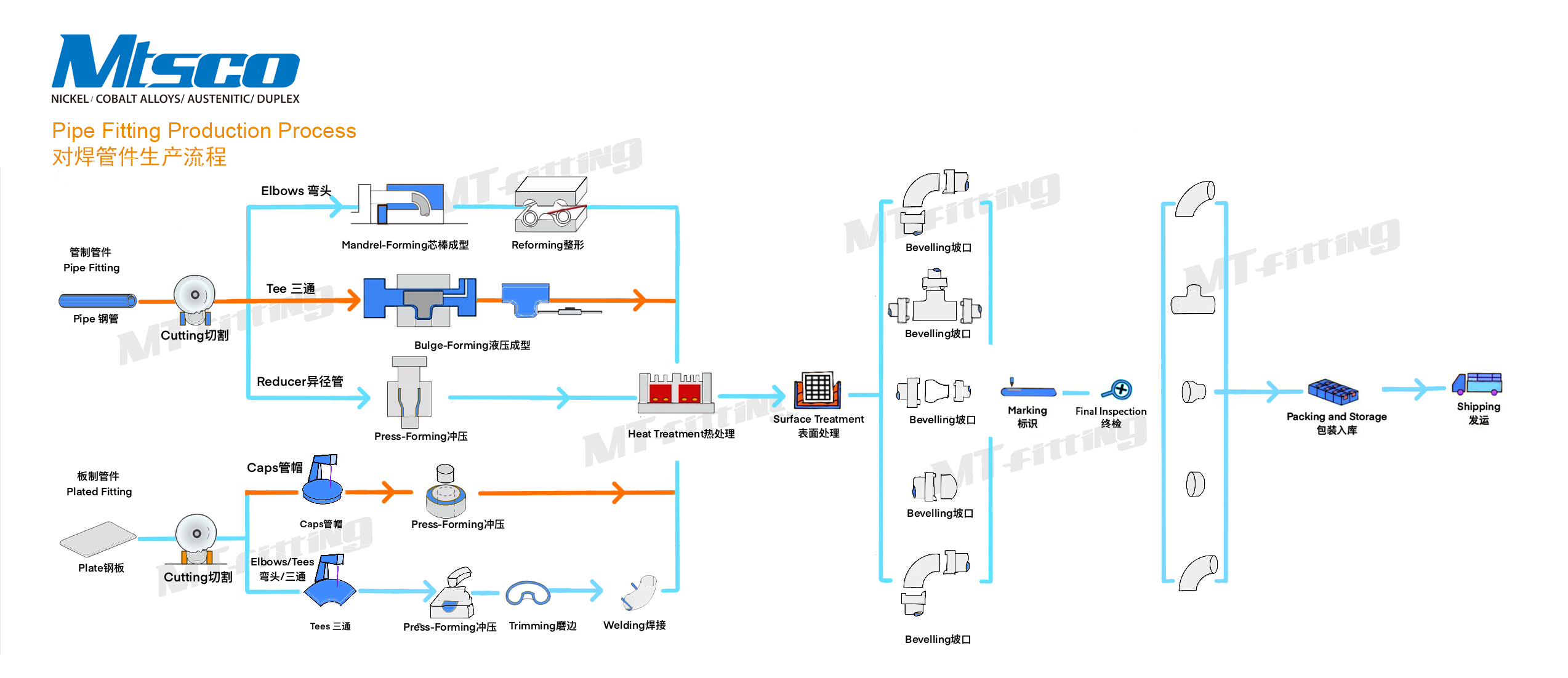

Pipe Fitting Manufacturing Process:

Cutting: Precisely size pipes to design specifications.

Forming: Shape via cold pressing, hot bending, or die forging methods.

Welding (segmented parts): Perform joint welding followed by weld seam polishing.

Heat Treatment: Mitigate internal stresses and optimize material strength.

Surface Treatment: Apply sandblasting, electroplating, or corrosion-resistant coatings.

Inspection: Validate dimensions, conduct pressure endurance tests, and execute non-destructive testing (NDT) for compliance certification.

How do we ensure the quality of pipe fittings?

1. Raw material control

Secondary verification ensures reliability

The raw materials we use are all from well-known domestic steel mills such as Baosteel, Qingshan, and Yongxin, with stable and reliable quality. Each batch of materials must be accompanied by a material warranty (MTC) and a positive material identification test (PMI) report before arriving at the factory. After arrival, we will conduct PMI analysis and related inspections again to double-verify its chemical composition and material properties to ensure that it meets production standards and customer needs.

2. Production process management

Full process tracking and quality control

Hongdi is equipped with advanced processing equipment, including CNC lathes, automatic laser cutting equipment, 1,000-ton hydraulic forming machines, elbow mandrel pushers and other key equipment. Each process is strictly controlled by experienced engineers and technicians. Quality inspectors track and take photos of key nodes throughout the process, and use standardized process flow cards for operation guidance to ensure that the products are traceable and consistent.

3. Inspection before delivery

Full inspection before delivery

MTSCO's quality inspection team conducts strict inspections on each finished product, including appearance inspection, PMI verification, size verification, quantity confirmation and non-destructive testing. According to product requirements, we will also carry out in-depth laboratory projects such as mechanical property testing, chemical analysis, and intergranular corrosion testing. For welded pipe fittings, raw materials and finished products must pass 100% ultrasonic or radiographic non-destructive testing.

In addition, we support independent audits by third-party inspection agencies such as SGS, TUV, and BV.

MTSCO has rich operating experience in packaging and container transportation. Large pieces are wrapped in plastic wrap, small pieces are sealed with foam film or plastic, and pearl cotton is added to the port position for protection. The outer packaging is handled with wooden boxes or pallets, and the container is reinforced with wooden strips and ropes to ensure transportation safety. All inspection data and packing processes are recorded and archived with photos to meet customer traceability requirements.